You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What to buy and why

- Thread starter drbandkgb

- Start date

- Location

- Central FL

If money was no object I'd probably look at a Warn but knowing me I'd probably go to Harbor Freight and get their 12K lbs winch and get the extended warranty on it...lol

- Location

- Central FL

Can't blame you there...lol

- Location

- North Alabama

My theory is always buy once....cry once. Save up for the Warn.

Last edited:

Hey Dave!

I have a SMITTYBILT X2O 8,000lbfor ya. Its been under water for 4 weeks straight, and still going. Only killed two fish in 4 weeks, so its fish friendly to

We're giving away a XRC 8,000lb this coming Sat Nov 12th. winner goes into a drawing for $1000 4WheelParts shopping spree!

I like that free pice

I have a SMITTYBILT X2O 8,000lbfor ya. Its been under water for 4 weeks straight, and still going. Only killed two fish in 4 weeks, so its fish friendly to

We're giving away a XRC 8,000lb this coming Sat Nov 12th. winner goes into a drawing for $1000 4WheelParts shopping spree!

I like that free pice

- Location

- Central FL

The above post sounds fishy... What do ya think?

- Location

- Brooklyn, NY

IMHO a WARN is the only winch. Every time I have seen other brands fail I'm glad I spent the extra money. I've run a XD9000i with MasterPull synthetic line for many years, it has never let me down.

- Location

- Columbus OH

I have a Smittybuilt XRC8, A good friend with a XCR10, an another friend who is a competitive rock crawler who just put a new H2O 8k on one of his race trucks. They might not be the fastest in the world but it has never left me stranded. If you can wait a short time I heard that smittybuilt is coming out with a new one that is an improvement on the existing XRC series. For the price they are hard to beat.

i have a recon 10.5k lb i got from truckandwinch.com with the GB they did for thenewx. ive only used it a few times for a few different things but i like it so far. i pulled my X out of a ditch created my a little brook with it, pulled a tree over as my dad cut it and pulled a car out of a ditch after they slid off the road in the snow storm last week.

I'm looking at getting ahold of a winch as well but funds are tight. I don't do it all the time but when I do go out and play in the snow I have

a tendancy to get myself stuck in snow ruts get while helping others out of the ditch in a snow storm. Any thoughts on capacity limits, Is 8k the minimum recommendation or.? what do you all think. (Not to hi-jack here just a thought)

Thanx

a tendancy to get myself stuck in snow ruts get while helping others out of the ditch in a snow storm. Any thoughts on capacity limits, Is 8k the minimum recommendation or.? what do you all think. (Not to hi-jack here just a thought)

Thanx

Generally you want 1.5 x the weight of your truck

SO I ended up buying the Smittybilt X2O 8K winch.. They dont offer then in synthetic yet So Ill be adding the line later...

So Ill be adding the line later...

399.99 right now on 4wd.com

Now I just have to wait on my new bumper to install it..

to install it..

SO I ended up buying the Smittybilt X2O 8K winch.. They dont offer then in synthetic yet

399.99 right now on 4wd.com

Now I just have to wait on my new bumper

- Location

- Columbus OH

Also think about the people that you wheel with also, I tend to wheel with a few full size and when they get stuck they really get stuck. A snatch block is something that can come in very handy, not only for increasing the power, but for changing the direction of the pull. I would consider an 8k a minimum for a vehicle the weight of an X.

The old rule was always 1.5x the GVWR of the rig....MINIMUM capacity.

This works well if you are not in deep mud, where its too light.

DOUBLE the GVWR is sometimes too light in that kind of mud....the kind you sink into and it pulls your boots off trying to get back out....That's even more than that.

The Duty Cycle is the most overlooked winch spec.

Its how long you can run the winch before you have to let it cool down again for a specified period.

The less expensive winches typically take advantage of the average consumer's lack of awareness on this, and use less expensive parts that overheat more easily, instead of expensive parts that can take a higher duty cycle.

Some also use gearing to get load capacity, at the expense of speed....and/or the "no load" weights and speeds are sweet looking on paper, but, quickly degrade under load.

IE: The 8k rated winch that pulls 48' per minute at zero weight, might be REALLY pulling at only 4k and at only 2' per minute under load with one wrap off the spool, etc.

The UNDER LOAD specs are rarely published in advertising, unless they're good typically.

Most winch makers do post the specs for amp draw, speed, duty cycle and weight capacity for wrap numbers, etc....on the web sites, or maybe in their manuals, etc.

The agonizing thing about a low duty cycle is that no one I know has the PATIENCE to actually FOLLOW the owner's manual instructions for cool down periods.

A cheap winch with a duty cycle that specifies 10 minutes of cooling for every 2 minutes of PULLING, and, under load, might be pulling ~ 2 fpm, can take a long time to drag your *** out of a mud pit.

Example:

You are stuck 90' from the nearest anchor point, and need to drag yourself 90' to get out...(Your tires are too small to reach, and your diffs/axles and frame/spring hangers are acting like giant tank traps/road graders)

OK, you pull for the 2 minutes, at 2 fpm, and have gone 4'...and now let it cool for 10 minutes.

To simplify the math, lets call this an EFFECTIVE RECOVERY RATE of ~ 4' in 12 minutes, or, an average of 0.33 fpm.

You need to go 90'

That's about 270 minutes, or about 4.5 hrs of recovery....and the day is shot.

Do the same recovery w/o worrying about burning out the motor, because, what the hey, its covered under warranty! - and just crank on it...and that's 45 min of recovery...assuming the winch doesn't fail and leave you stranded.

Do the same recovery with a better/faster winch, with an effective recovery speed of say 8 fpm, and its done in about 11 minutes or so....and you go play again.

So, I've seen HF winches, Smitty's, MM's, and so forth on the trails, and I've seen ALL makes fail at one time or the other...but the failure RATES were miniscule for Warn, and waaay up there for a lot of the others with low duty cycles.

I know guys on their 8th or 9th winch for example.

So, I think it comes down to how mission critical the part is. If failure of the winch would leave you stranded in a bad place, or be enough of a bummer that you'd have upgraded if you KNEW it was going to fail....then get a Warn made here in the USA.

If you wheel with a bunch of people who also have winches, and/or where you are not in any deep doo doo if the winch craps out on you....and its not a big deal to throw it into a box once in a while, and get a new one under warranty.....then, sure, the el cheapo's are a good deal.

Add to the consideration that you may, or may not, have the patience to WAIT for duty cycle cooling periods....and, NOT waiting tends to damage the winch over time...IE: It might WORK a few times, and THEN crap out on you, etc....from cumulative over heating damage....when deciding on HOW often is ok for those warranty trips.

Food for thought.

This works well if you are not in deep mud, where its too light.

DOUBLE the GVWR is sometimes too light in that kind of mud....the kind you sink into and it pulls your boots off trying to get back out....That's even more than that.

The Duty Cycle is the most overlooked winch spec.

Its how long you can run the winch before you have to let it cool down again for a specified period.

The less expensive winches typically take advantage of the average consumer's lack of awareness on this, and use less expensive parts that overheat more easily, instead of expensive parts that can take a higher duty cycle.

Some also use gearing to get load capacity, at the expense of speed....and/or the "no load" weights and speeds are sweet looking on paper, but, quickly degrade under load.

IE: The 8k rated winch that pulls 48' per minute at zero weight, might be REALLY pulling at only 4k and at only 2' per minute under load with one wrap off the spool, etc.

The UNDER LOAD specs are rarely published in advertising, unless they're good typically.

Most winch makers do post the specs for amp draw, speed, duty cycle and weight capacity for wrap numbers, etc....on the web sites, or maybe in their manuals, etc.

The agonizing thing about a low duty cycle is that no one I know has the PATIENCE to actually FOLLOW the owner's manual instructions for cool down periods.

A cheap winch with a duty cycle that specifies 10 minutes of cooling for every 2 minutes of PULLING, and, under load, might be pulling ~ 2 fpm, can take a long time to drag your *** out of a mud pit.

Example:

You are stuck 90' from the nearest anchor point, and need to drag yourself 90' to get out...(Your tires are too small to reach, and your diffs/axles and frame/spring hangers are acting like giant tank traps/road graders)

OK, you pull for the 2 minutes, at 2 fpm, and have gone 4'...and now let it cool for 10 minutes.

To simplify the math, lets call this an EFFECTIVE RECOVERY RATE of ~ 4' in 12 minutes, or, an average of 0.33 fpm.

You need to go 90'

That's about 270 minutes, or about 4.5 hrs of recovery....and the day is shot.

Do the same recovery w/o worrying about burning out the motor, because, what the hey, its covered under warranty! - and just crank on it...and that's 45 min of recovery...assuming the winch doesn't fail and leave you stranded.

Do the same recovery with a better/faster winch, with an effective recovery speed of say 8 fpm, and its done in about 11 minutes or so....and you go play again.

So, I've seen HF winches, Smitty's, MM's, and so forth on the trails, and I've seen ALL makes fail at one time or the other...but the failure RATES were miniscule for Warn, and waaay up there for a lot of the others with low duty cycles.

I know guys on their 8th or 9th winch for example.

So, I think it comes down to how mission critical the part is. If failure of the winch would leave you stranded in a bad place, or be enough of a bummer that you'd have upgraded if you KNEW it was going to fail....then get a Warn made here in the USA.

If you wheel with a bunch of people who also have winches, and/or where you are not in any deep doo doo if the winch craps out on you....and its not a big deal to throw it into a box once in a while, and get a new one under warranty.....then, sure, the el cheapo's are a good deal.

Add to the consideration that you may, or may not, have the patience to WAIT for duty cycle cooling periods....and, NOT waiting tends to damage the winch over time...IE: It might WORK a few times, and THEN crap out on you, etc....from cumulative over heating damage....when deciding on HOW often is ok for those warranty trips.

Food for thought.

- Location

- Dayton, OH

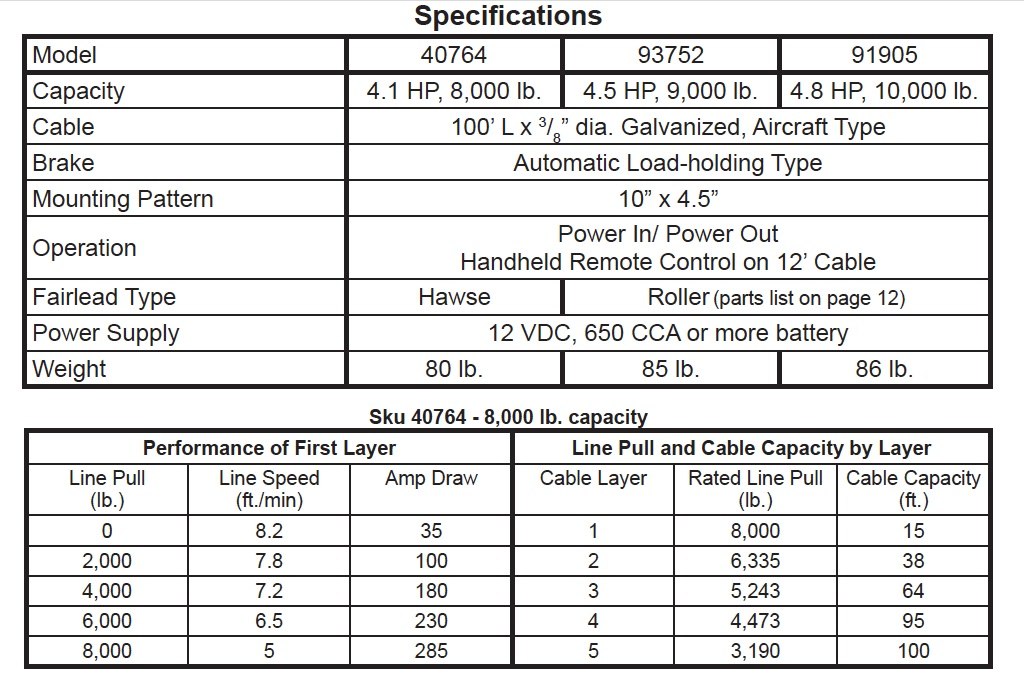

So TJ since you have all the knowledge, what exactly does the BOLD area below mean? That you can use it for 45 seconds, then you have to wait 14 mins? But the rest cycle was listed as the 15 seconds? I'm slightly confused and I just grabbed the first specs I could find (HF Winch btw). Also, what would you be looking for in the gear ratio? I've seen anywhere from 150-250 ish between the couple I looked at quick

Duty Cycle Rating

5% (45 sec at Max Rated Load; 14 min, 15 sec Rest)

Gear Ratio

218:1

Duty Cycle Rating

5% (45 sec at Max Rated Load; 14 min, 15 sec Rest)

Gear Ratio

218:1

So TJ since you have all the knowledge, what exactly does the BOLD area below mean? That you can use it for 45 seconds, then you have to wait 14 mins? But the rest cycle was listed as the 15 seconds? I'm slightly confused and I just grabbed the first specs I could find (HF Winch btw). Also, what would you be looking for in the gear ratio? I've seen anywhere from 150-250 ish between the couple I looked at quick

Duty Cycle Rating

5% (45 sec at Max Rated Load; 14 min, 15 sec Rest)

Gear Ratio

218:1

OK, the first part means that it has a 5% duty cycle, so, essentially, it needs to rest 95% of the time your using it to cool down...

...and, you can't pull for more than 45 seconds at a time, or it will overheat/fail.

After you do your 45 SECOND pull, you let it COOL OFF FOR FOUR MINUTES AND 15 SECONDS.

The second part means that its geared so that 218 motor RPM = ONE SPOOL RPM.

So, to translate that into performance, you'd ALSO need to know the line speeds it can pull with various weight, typically listed in a chart with say 4-5 weights from 1-2k lb up to the rated capacity of the winch.

That chart often also lists how much WEIGHT it can pull with various amounts of line on the SPOOL.

The reason that's important is that the SPOOL acts like a gear too....and when there's LOTS of line wrapped on it still, its got a larger effective diameter...so, it can have a faster line speed, but, can't pull as much weight, etc...

If the line is all played out for a long pull for example....that first wrap back onto the spool is where the most POWER is, but, the slowest SPEED, because the effective spool size as a gear is smallest....and so forth.

I don't know if this is the same Harbor freight 8k Winch, but, its specs for the one on their web site currently:

So, look at the specs for 1st wrap vs 5th wrap for example...Its an 8k winch, but its closer to a 3k winch if there's a bunch on line on the spool, and its pulling at 8 fpm with no load, and ~ 5 fpm with a full load, etc.

That means that it can drop down to less than 40% of its rated capacity under use...if you have a 5k lb rig to recover, and only ~ 3k of pulling power...well, it can be a long day.

So, for this winch, you can only pull for 45 seconds at a time, and then you have to wait about 14 minutes or so for it to cool off enough to do ANOTHER 45 seconds of pulling.

Lets take the same 90' recovery...

You pull it for 45 seconds at 5 fpm...moving the recovery along about 3.75'.

You let it rest for about 14 minutes, and pull another 45 seconds....and go ANOTHER 3.75'.

If you simplify the math a bit, that's about 15' per hour as your effective recovery rate.

THAT means that 90' will take you about SIX HOURS.

I don't know about you, but that is too slow for me...I don't have the patience to waste a day of wheeling waiting for something like this to take 6 HOURS, instead of say 11 minutes with a real winch.

So, obviously, a winch with a 5% duty cycle can be made less expensively than one that can run for say a half hour or so w/o a break...and, if its a cheap winch, or sitting in the pine barrens over night because you couldn't leave because you were too stuck to get out w/o a winch...that you have to choose between, sure, "Slow" can be better than "No", etc.

Of course, a LOT of pulls are shorter than that, sometimes just a few foot "Boost" of of a jamb, etc...and, most pulls are not full capacity...if you are on trails with rocks, dirt/berms, etc, you might just need a little help getting up a slippery slope, etc, rather than to be hauled up a tree a la "The gobbles Must Be Crazy" , etc.

Pulling a rig up a slope (THINK RAMP) takes less force than the weight of the rig, making the pull easier, luckily.

If you only need 45 seconds to a couple of minutes at 5-8 feet per minute (~ 4' - 14'or so of light pull), you're good to go.

If you need to

Me, I'd rather have something fast enough to leave time for wheelin', strong enough to DO the recovery....and reliable enough that it won't strand me.

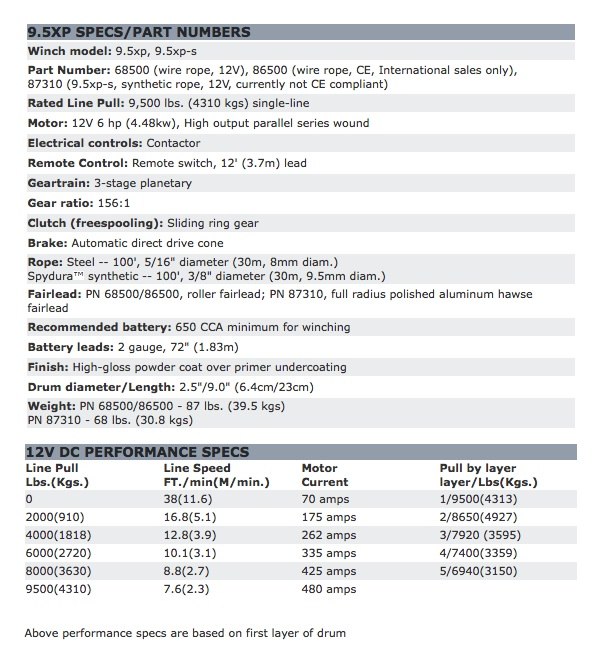

For comparison, at an opposite end of the scale, here are specs for a Warn 9.5xp, closer to what I think we should have as far as rated capacity:

Notice at no load, its more like 38 fpm than 8 fpm...and at a load of 8k lb, its STILL pulling at almost 9 fpm, faster than the HF winch could with zero load.

Even on the 5th wrap, its still able to pull more than twice the HF's load, and the most it drops is about to 73% of its rated capacity, not all the way down to UNDER 40% like the Harbor Freight Winch.

Its a 6 HP motor with 156:1 gearing, instead of the HF's 4.1 HP motor and 218:1 gearing.

Obviously, a higher HP motor is more expensive if its made to be reliable, and, as its stronger, it can pull the same weight faster, or, more weight slower, depending on the gearing its equipped with.

Weaker winch motors use higher (Numerical) ratios to get more mechanical advantage, at the expense of speed...like pedaling your bike up a steep hill in 1st gear instead of in 10th, etc.

That means that there's no "Right" gear ratio...higher numerical ratios mean, for a given MOTOR RPM, the winch is pulling SLOWER, and, lower numerical ratios means that for the same motor RPM, its pulling FASTER, and so forth.

If its a strong motor, a lower ratio gear is cool, as it give s faster line speed.

If its a weaker motor, you NEED a higher ratio to be ABLE to move the load...and give up the line speed to do it.

Of course, I paid about $600 for MY Warn 9.5xp when they first came out...and its never had so much as a hiccup in use....and it gets used a lot, I take a lot of people through the Pine Barrens for example, and mud bogging is a winch fest.

So, sure, not every one can afford a good winch...and not every one can afford to be stuck with a cheap winch.

Everyone has to decide for themselves what makes sense for THEM.

Last edited:

awesome info man! thanks for writing this up

Sometimes I can be helpful

- Location

- Lancaster, Pa

Great info as usual TJ. Hope to see ya at the northern Xposure run.

- Location

- Dayton, OH

Thanks TJ! I appreciate the expertise! Since I've got a new bumper coming I'm trying to get all of this figured out, thanks again!

- Location

- IL

- Location

- Dayton, OH

Another n00b question, is the synthetic line mitigating the kinetic force held in the steel wire if it were to snap? This way it would just fall to the ground rather than snapping and going any which way?

- Location

- Columbus OH

synthetic lines do not streatch when under load like wire rope does. Since they dont store any energy they just drop where they are instead of recoil.

- Location

- Carlisle, Iowa

Mine doesnt seem to stretch heres a vid explaining benefits

http://www.youtube.com/watch?v=GDJ3QjvRZT0

http://www.youtube.com/watch?v=GDJ3QjvRZT0

- Location

- Morrison, CO

The weaving gives the appearance of stretch, but the individual strands do not stretch. We've got Synline on our Warn 9.5ti and it's awesome!

I've had to yank my wife's friend from our neighbor's driveway with it and yank myself out of the driveway with it. That line is great.

I've had to yank my wife's friend from our neighbor's driveway with it and yank myself out of the driveway with it. That line is great.

- Location

- IL

so how is your winch rated dave ? as in how long does it pull and how long does it need to cool down?

- Location

- S.Subs of Chicago, IL.

:questions: For the money and wear it seems Warn is the choice. With that understanding, Warn makes one w/ OBA. Since I am planning to someday add ARB lockers, is the OBA optioned winch the Endurance 12.0 (which is the 9.5xp) worth it? Or is it better to get them seperate?

- Location

- Morrison, CO

We've installed several of the winches with the OBA on the Jeeps, they're huge!

But really, I'd get them separate. Hate to lose the OBA if the winch takes a dump in the middle of a trail, which means you also loose your lockers.

With ARB's, I like the OBA option, but I also like an aux tank for power tools or a separate CO2 tank with an adapter to be able to plug into the ARB lines so you can still use the lockers in case of a failure.

But really, I'd get them separate. Hate to lose the OBA if the winch takes a dump in the middle of a trail, which means you also loose your lockers.

With ARB's, I like the OBA option, but I also like an aux tank for power tools or a separate CO2 tank with an adapter to be able to plug into the ARB lines so you can still use the lockers in case of a failure.

R

ryandavenport

Guest

Allen, what is an acceptable tank size to run for powertools?

And so I don't threadjack, I love winches.

And so I don't threadjack, I love winches.

- Location

- Columbus OH

Tank size is directly proportional to compressor size, flow rate, and duty cycle. The larger the compressor, the higher duty cycle, the better flow rate, the smaller the tank. And vice versa, the smaller duty cycle, the bigger the tank. Most fall somewhere in between.

Like Allen I like to keep my winch seperate from my air scource. The main draw on air tools is is the size and weight when compaired to battery powered. Unless you are going to run a lot of air tools, or expect to do a lot of trail repairs then battery powered is usually sufficient.

For just running bolts in and out, a 3/8 impact with LI battery will work just fine. If there is a bolt that is stuck, just use a breaker bar to loosten it, and the impact to run it in or out.

I dont even carry a 1/2 inch breaker any more, just a 3/8 with a cheater that takes it out to about 2 feet. I have yet to find one that I could not loosten with it.

Like Allen I like to keep my winch seperate from my air scource. The main draw on air tools is is the size and weight when compaired to battery powered. Unless you are going to run a lot of air tools, or expect to do a lot of trail repairs then battery powered is usually sufficient.

For just running bolts in and out, a 3/8 impact with LI battery will work just fine. If there is a bolt that is stuck, just use a breaker bar to loosten it, and the impact to run it in or out.

I dont even carry a 1/2 inch breaker any more, just a 3/8 with a cheater that takes it out to about 2 feet. I have yet to find one that I could not loosten with it.