robcarync

Sliders

- Location

- Raleigh, NC

I have gotten my X on the beach once before, back in May for my Bachelor Party!!!! It was awesome, I didn't get stuck, but some sections of the beach were very loose sand, and there was not a lot of forward momentum at all. My engine did start to overheat...which was a bummer. Engine still running strong though. I was driving in 4 Lo the entire time and had my auto transmission lever in 2...but did not air down my tires.

I am going out to the same spot again this weekend, and am trying to make sure I am driving the way I should. Google gives interesting debates and inconsistent answers as far as whether to use 4Hi or 4Lo.

I know the common sense stuff: don't spin your wheels and get yourself buried to your frame, etc...but this time around I will:

1) Have my radiator relocated so it is more in line with the fan and able to use fan shroud.

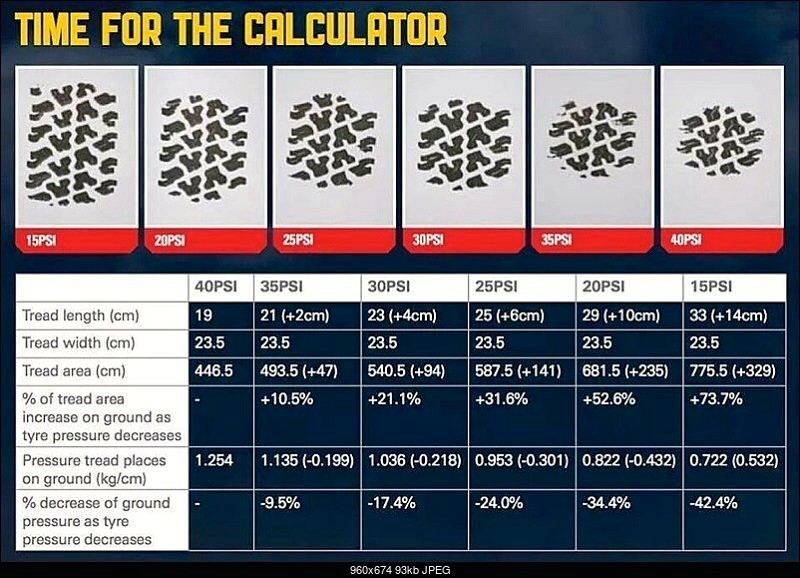

2) Lower tire pressure like I am supposed to.

3) Give my cooling system a once over to make sure it is in good condition and filled with proper fluid levels.

So question is:

1) What is the actual best transfer case gear to be in? 4Hi? 4Lo?

2) What is the best automatic transmission gear to be in? 1? 2?

2) Any other tips for navigating through the sand?

I am not so much concerned about getting stuck. I have a front Lokka, straps and shackles, a shovel, and a hi lift...just looking to reduce the potential for over heating and be efficient in my navigation.

I am going out to the same spot again this weekend, and am trying to make sure I am driving the way I should. Google gives interesting debates and inconsistent answers as far as whether to use 4Hi or 4Lo.

I know the common sense stuff: don't spin your wheels and get yourself buried to your frame, etc...but this time around I will:

1) Have my radiator relocated so it is more in line with the fan and able to use fan shroud.

2) Lower tire pressure like I am supposed to.

3) Give my cooling system a once over to make sure it is in good condition and filled with proper fluid levels.

So question is:

1) What is the actual best transfer case gear to be in? 4Hi? 4Lo?

2) What is the best automatic transmission gear to be in? 1? 2?

2) Any other tips for navigating through the sand?

I am not so much concerned about getting stuck. I have a front Lokka, straps and shackles, a shovel, and a hi lift...just looking to reduce the potential for over heating and be efficient in my navigation.